Fabric Testing and Fabric Testers

The testing items in the textile testing laboratory are divided into fiber testing, yarn testing, and fabric testing according to material classification. In the following content, we will introduce the relevant information on fabric testing according to the different properties of fabrics.

Contents

The fabric solid degrees

During the use of fabrics, the most basic forms of mechanical damage are tensile fracture, tearing, bursting and abrasion.

Tensile performance testing

The law of mechanical deformation of the fabric when it is stretched by external forces along the warp and weft directions.

Electronic strength tester is used to determine the mechanical property of woven fabric, non-woven fabric, knitted fabric, including tensile, tearing, seam slippage, elastic recovery, etc.

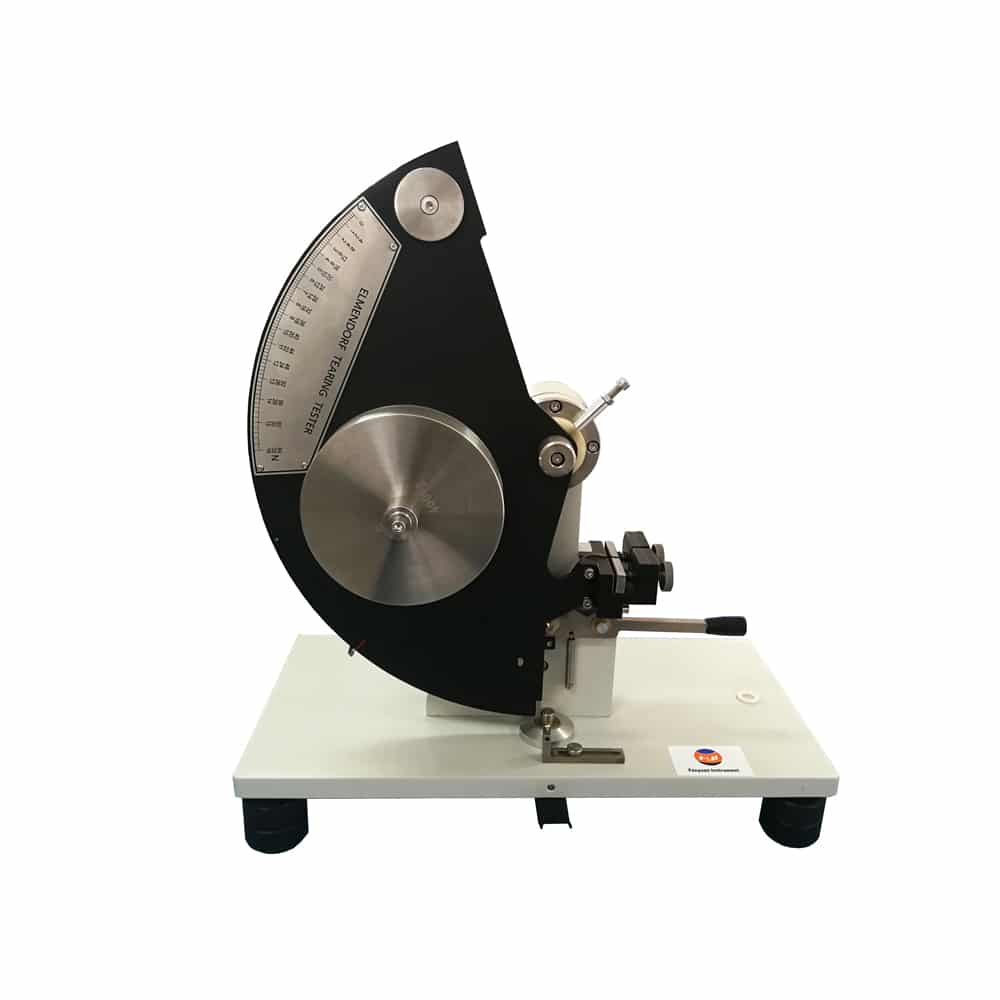

Tear testing

The phenomenon that the edge of the fabric is subjected to a concentrated load and the fabric is torn is called tearing.

Elmendorf Tear Tester is used to determine the tear force of woven fabric, thick paper, plastics cloth, etc., with suitable ballistic pendulum range from 16 to 64 Newton( YG033A ),Range from 32000 to 128000 Newton ballistic pendulum ( YG033B).

Bursting performance test

The rupture of the fabric caused by the force perpendicular to the cloth surface is called bursting. In the actual test, a steel ball is often used to exert force on the fabric until the fabric breaks.

Bursting Strength Tester is used to determine the bursting strength and the bursting distension of textile fabrics, such as knitted, woven, nonwoven and laminated fabrics or other fabrics produced by other techniques.

Abrasion testing

The surface damage caused by repeated tangential friction on the fabric surface is called wear.

Due to different specific wear methods, different damage effects will be produced, so the laboratory has many types of instruments when testing wear. According to the form of action, it is divided into flat grinding (according to the friction direction of the fabric, it is divided into three types: reciprocating type, rotary type and Martindale multi-directional type), curved grinding, hemming grinding, compound grinding and turning grinding.

The Martindale Abrasion Tester is suitable for determining the abrasion resistance of most textiles (including woven fabrics, knitted fabrics, nonwovens, ramie, silk, etc.) under slight pressure.

Taber abrasion tester is suitable to conduct wear resistance test for different materials, such as cloth, paper, paint, plywood, leather, floor tiles, natural rubber, etc.

Fabric appearance retention

Pilling

In the process of wearing and washing, the fabric is constantly subjected to friction, rubbing, etc., and the surface of the fabric will produce hair (fluff), and if it continues to be rubbed, these hairs will become entangled with each other into balls (pilling), and the weaving appearance will deteriorate (deterioration).

The surface pilling tester is used to test the pilling of wool fabrics and chemical fiber pure spinning, blending, knitting and machined fabrics to identify product quality or process effects. The instrument uses a positive friction mechanism to make the sample move reasonably relative to each other under certain friction conditions. The inspection of fabric pilling can be completed in a short time to identify product quality and improve production process. Provide reliable test data.

Snagging

The yarn in the fabric is hooked out of the fabric by a sharp object, and causes pulling silk marks on the surface of the fabric. Snagging will deteriorate the appearance of fabrics, and snagging resistance is one of the important wearable properties of fabrics, especially knitted outerwear fabrics.

The Snag Resistance Tester is used to determine the tendency of a fabric to snag (loops of yarn pulled from the fabric) during normal wear. It is suitable for woven and knitted fabrics such as textured yarn, non-deformed yarn, and spun yarn, but not for mesh fabric, tufted fabric, non-woven fabric, etc.

Wrinkle resistance

Wrinkle resistance refers to the ability of a fabric to resist bending and deformation under the action of external rubbing forces. The appearance of general fabrics is generally smooth, flat, and wrinkle-free without any external force. However, after use, the surface of the fabric loses its original characteristics, produces wrinkles, loses its flatness, and looks ugly and unsightly.

The fabric wrinkle recovery tester is used to measure the recovery ability of fabrics after being creased, and is expressed by the crease level method; the tester is suitable for fabrics of various thicknesses and can obtain fast and slow crease recovery in indoor environments. index.

Drape

The drape of a fabric refers to the degree and shape of the fabric when it sag due to its own weight. The degree of drape refers to the degree to which the fabric drapes under its own weight. The greater the sag, the better the drape of the fabric. Draping morphology refers to the characteristics of the extended portion of the fabric that can form a uniform, smooth and high-frequency undulating surface.

The automatic fabric drape tester is used to determine the drape index, drape coefficient, activity rate, ripple number and coefficient of various fabrics.

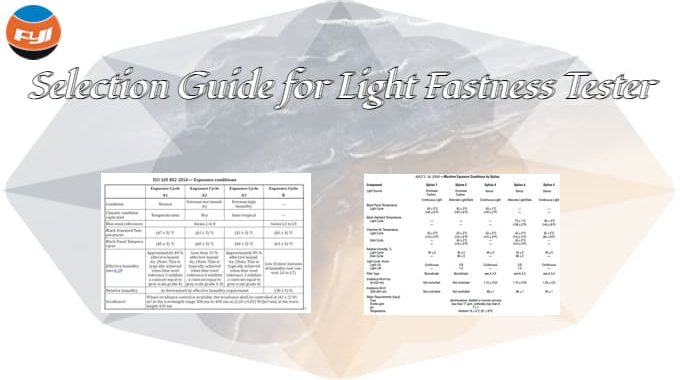

Color fastness

Fabrics will fade under the effects of sunlight, washing, soaping, friction, sweat stains, ironing, bleaching, sea water, dry cleaning, etc. This performance has the most testing methods. The main evaluation method is to use a standard gray sample card to compare and evaluate the color fastness. You can also use a colorimeter to test the color difference.

Fabric Dimensional Stability

Fabrics may change their size when exposed to moisture, heat, washing, etc. The shrinkage of fabrics under the influence of external factors is called shrinkage, and the ability to resist dimensional changes is called dimensional stability. There are many reasons for fabric shrinkage, such as expansion and shrinkage of fibers after absorbing water (i.e. shrinkage), slow elastic shrinkage, curling and shrinking of macromolecules under the action of heat, felting shrinkage of wool, etc. The shrinkage of clothing fabrics not only affects the appearance and comfort of the wearer, but also affects its continued use performance.

The washing shrinkage tester is used as accelerated washing equipment for knitted and woven fabrics to evaluate shrinkage in accordance with international testing methods.

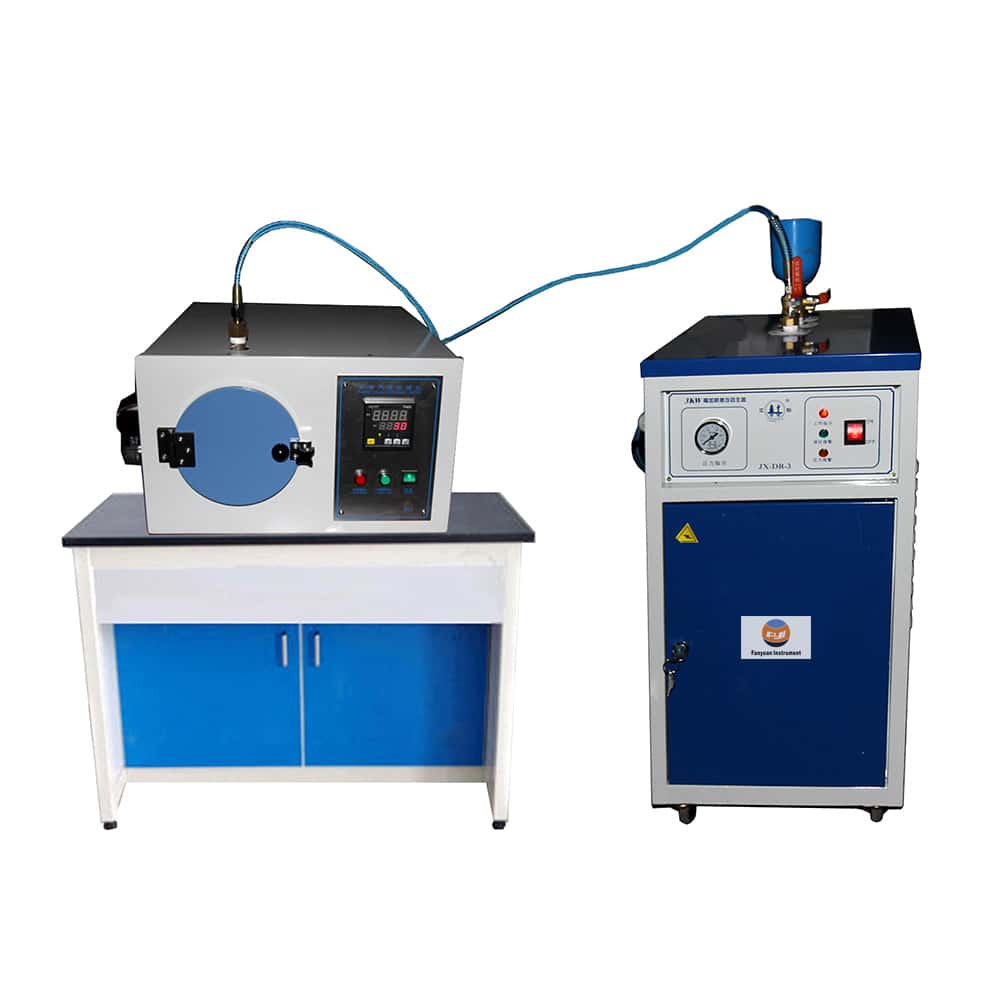

The fabric steam shrinkage tester is used to measure the dimensional changes of fabrics under the action of free steam. It is suitable for testing woven fabrics, knitted fabrics and fabrics with poor dimensional stability.

Fabric comfort

Comfort is the physiological feeling of the human body to the fabric, and is often evaluated based on the discomfort of the human body to the fabric. It involves specific content such as fabric permeability and thermal and moisture comfort.

Air permeability

Air permeability means the performance of air permeability through fabric. Under specified pressure difference conditions, the air flow rate vertically passing through a given area of the sample within a certain period of time is measured, and the air permeability is calculated. The air flow rate can be measured directly or converted by measuring the pressure on both sides of the flow aperture.

The air permeability tester is calculated by measuring the flow rate of the air flow perpendicular to a given area of the sample within a certain period of time under specified pressure difference conditions. Complying with various testing standards such as GB, ISO, ASTM, etc., the pressure difference can be set to meet different requirements.

Moisture permeability

Moisture vapor permeability is expressed in units of g/m2/24h. It refers to the formation of a specific humidity difference on both sides of the sample under certain standard laboratory conditions. Water vapor enters the dry side through the sample, and parameters such as the water vapor transmittance of the sample can be obtained by measuring the change in weight of the moisture-permeable cup over time.

The water vapor permeability tester is used to measure the water vapor transmission rate of fabrics, coated fabrics, composite materials, clothing, industrial fabrics, etc.

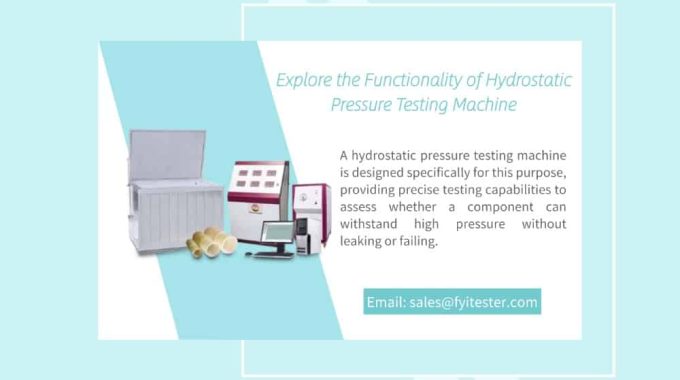

Water permeability

Water permeability refers to the ability of liquid water to penetrate from one side of a fabric to the other.

Water repellency tester evaluates the moisture content and water resistance of the test sample by measuring the moisture content in the water cup and the moisture content on the cloth surface.

Digital hydrostatic tester is used to determine the water penetration resistance of fabrics (such as canvas, tarpaulin, manta, tent cloth, rainproof clothing) under hydrostatic pressure.

Fabric style and feel

Fabric style is a comprehensive judgment made by the physical and mechanical properties of fabrics acting on human sensory organs.

The broad fabric style includes visual style and tactile style. Visual style refers to the comprehensive physiological and psychological reflection of the fabric’s appearance characteristics, such as color, pattern, lightness, texture, flatness, smoothness, etc., that stimulate people’s visual organs and cause people to have it. Tactile style is a comprehensive evaluation of the stimulation of people through the touch and grasp of human hands and the physical and mechanical properties of fabrics. Tactile style is also called narrow style or feel.

The fabric touch tester measures bending, compression, friction and tension by simulating the stretching, compression, pinching and kneading movements of the hand touching the fabric. Measuring skin touch performance, obtaining indicators such as softness, stiffness, smoothness, tightness, etc., and objectively evaluating the feel and feel of fabrics.

Comments are closed.

These fascinating facts and statistics presented in the blog is good.

Know what I love about this writer? They have a knack for making complex topics accessible and easy to grasp.

As someone who loves to explore new topics, joining the journey of reading this article was an absolute delight.

To say that this article is well-written would be an understatement; it is a masterful piece of storytelling.