4 Knitted Fabric Defects in Circular Knitting Machine

The Knitted fabric defects in circular knitting machine affect the aesthetic degree of cloth. Many people hate them but can’t do anything about them. In this article, I will show you the solutions to these knitted fabric defects.

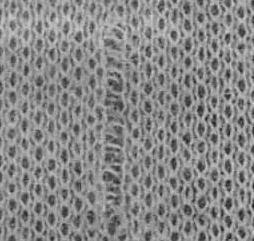

Leakage needle

In the process of knitting, the knitting needle does not hook the wool yarn. Or hook the wool yarn and then comes out of the needle hook to form the coil detach, vertical striations and holes appear in the cloth. This is the most common knitted fabric defect.

| Causes | Solutions |

| Needle tongue is closed. | Open the tongue of the needle. |

| Two knitting needles merged into a circle. | Divide the knitting needles into circles. |

| The needle hook can no longer hook yarn. | Replace knitting needles. |

| The position of the pin plate is incorrect, affecting the gasket. | Adjust the position of the pin plate to ensure that the yarn is passing through the needle hook. |

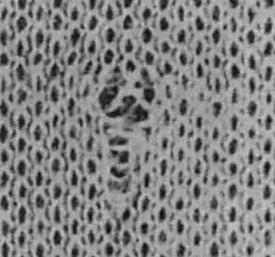

Holes

Fabrics with small or large holes. The coil breakage causes the holes in the cloth.

| Causes | Solutions |

| The yarn joint is too big. | The knot should be flat. |

| After the needle tongue falls off or slants, it cannot retreat. | Replace the knitting needle. |

| The intensity fabric is too spare and tight. | Open thin fabric properly. |

| The position of gasket is not correct. | Adjust the position of the gasket so that the needle tip does not insert the yarn. When the needletongue is closed, don’t clip the yarn. |

| The material size does not match the needle numbers of machine. | Reselect the knitting machine that matches the number of needles according to the thickness ofthe raw material. |

Fur

The fabric has broken fibers on the surface. This knitted fabric defect occurred when the circular knitting machine was mishandled.

| Causes | Solutions |

| The lead holes passing through the yarn are severely worn. | Replace worn feeder ring. |

| The coordination with the knitting needle and the sinker is not coordinated. | Adjusting the cooperation between the knitting needle and the sinkers. |

| The position of gasket is not correct | Adjust the position of the gasket. |

| The weft storage device is not evenly wound. | Adjust the winding volatility. |

| The tension of yarn is over large. | Reduce the volatility strength of yarn properly. |

Horizontal strip

As the length of the coil is not the same, the fabric is different in thinness.

| Causes | Solutions |

| Volatility is unstable. | Eliminate the factors of fluctuation and increase force, making the volatility stable. |

| The mouth of feeder line passing through the yarn is not smooth. | Replace the feeder coil. |

| The storage weft device is not smooth. | Grinding the gauze drum. |

| The matching with the knitting needle and the sinkers is not coordinated. | Adjust the matching between the knitting needle and the sinkers. |

| The storage lines are uneven. | Adjust the winding volatility. |

| The insert panel is seriously worn. | Replace the inserting panels. |

There are many other knitted fabric defects in circular knitting machine I have not mentioned. Maybe I will write another blog about this in the future. You can write a comment below or send emails to [email protected] if you have any questions.

Comments are closed.

An very fascinating go by means of, I might not concur entirely, nevertheless you do make some genuinely legitimate factors.

Your writing style in this blog conveys both professionalism and authenticity.

That blog post was filled with thought-provoking questions that engaged readers on a deeper level.

From start to finish, this article kept me engaged with its insightful analysis and thought-provoking arguments.