Combing Process in Spinning

Before processing cotton, wool, and silk fibers into fabrics, the process of removing impurities and short fibers in the fibers with a combing machine is called combing. The texture, washability and durability of the fabric produced through this process are greatly improved compared with carded fabrics. The following introduces the composition of the combing machine and the combing process.

Contents

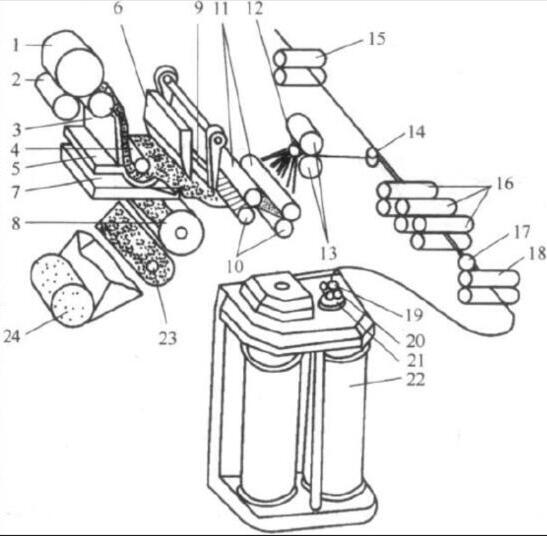

Mechanism composition of combing machine

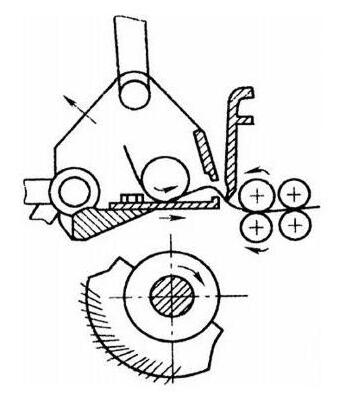

The mechanism composition of the combing machine: feeding mechanism, clamping mechanism (holding), carding mechanism, extraction and separation mechanism, stripping mechanism, and cleaning mechanism.

| 1. Small roll | 2. Roller | 3. Roll guide | 4. Give Cotton Roll |

| 5. Feed board | 6. Upper nipper | 7. Lower nipper | 8. Combed cylinder |

| 9. Top comb | 10. Separation roller | 11. Separation stick | 12. Aggregator |

| 13. Car surface pressure stick | 14. Guide nail | 15. Middle pressure stick | 16. Drafting mechanism |

| 17. Aggregator | 18. Large pressure spoke | 19. Coil Collector | 20. Coil |

| 21. Helical tube gear | 22. Canister | 23. Brush | 24. Dust cage |

Combing process in spinning

The kinematic coordination relationship of the main parts on the combing machine is indicated by a dial. The disc is mounted on the combing machine and rotates synchronously with the cylinder, which is generally called the indexing disc. The index plate is divided into 40 equal parts along the circumference, and each equal part is 9°, which becomes one index.

The working cycle refers to the time interval between the combing cylinder of the intermittent combing machine corresponding to the two actions of combing the whiskers. That is: the first row of needles in the combing cylinder goes to the bottom of the jaws to the first row of needles to the bottom of the jaws again, and one work cycle is also often called a clamp time.

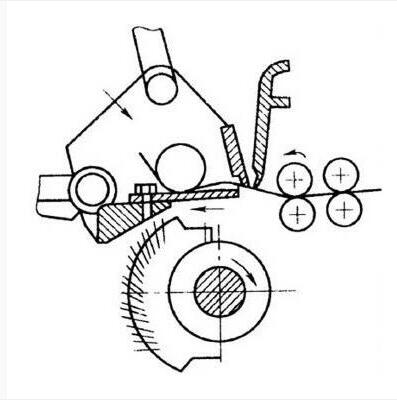

A movement cycle of a combing machine can be divided into four stages:

- Cylinder carding stage.

- Preparation stage before separation.

- Disengagement engagement phase.

- The preparatory stage before cylinder carding.

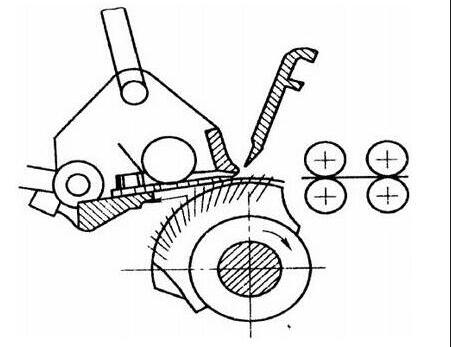

Cylinder carding stage

Cylinder carding starts from the first row of needles in the cylinder until the last row of needles leaves the cotton clump. At this stage, the working and movement conditions of the main parts are as follows:

Nippers: The upper and lower nippers are closed to firmly hold the barbels, and the nippers move first backwards and then forwards.

Cylinder: Comb the front end of the beard to remove short fluff and impurities.

Top comb: swing first and then forward (not involved in combing), but not in contact with whiskers.

Separation roller: in a basically static state.

Cotton feeding roller: stop feeding cotton.

Preparation stage before separation

The preparatory stage before separation starts from the end of cylinder carding to the start of separation. At this stage, the working and movement conditions of the main parts are as follows:

Nippers: The upper and lower nippers gradually open from closed, the nippers continue to move forward, and the jaws gradually open.

Cylinder: Keep turning without combing the cotton clumps.

Top Comb: Continue to swing forward and start to touch the cotton tufts.

Separation roller: From stationary to inverted, pour the cotton web into the machine, ready to be combined with the fiber bundle sent by the nipper.

Cotton feeding roller: start to feed cotton.

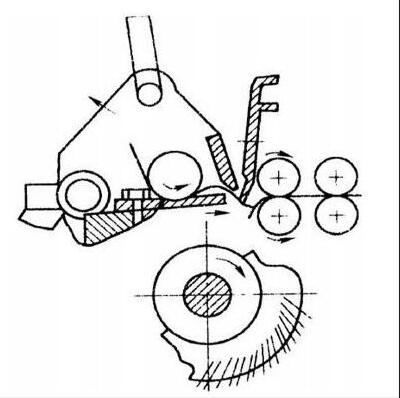

Disengagement engagement phase

The separation and splicing stage starts from the beginning of separation of fibers to the end of separation. The working and movement conditions of the main parts at this stage are as follows:

Nippers: The openings of the upper and lower nippers are enlarged, and continue to move forward to send the whiskers into the separating jaws.

Cylinder: Keep turning without combing the cotton clumps.

Top comb: Swing backwards, insert into the beards for combing, keep neps, impurities and short fibers in the beards behind the top comb, and be taken away by the cylinder in the next working cycle.

Separation roller: rotate clockwise, pull out the fibers sent by the nipper, and superimpose them on the end of the original cotton web for output.

Cotton feeding roller: continue to feed cotton.

The preparatory stage before cylinder carding

The preparatory stage before cylinder carding is from the end of separation to the start of cylinder carding. The work and movement of the main parts at this stage are as follows:

The preparatory stage before cylinder carding is from the end of separation to the start of cylinder carding. The work and movement of the main parts at this stage are as follows:

Nippers: The upper and lower nippers swing backwards and gradually close;

Cylinder: Continue to rotate, the first row of needles gradually approaches the bottom of the nipper, ready for combing;

Top Comb: Swing backwards and gradually break away from the cotton clump;

Separating roller: continue to output the cotton web in clockwise rotation, and gradually tend to stand still.

Cotton feeding roller: stop feeding cotton.

Advantages and disadvantages of combed cotton

Combing refers to a process of treating cotton. Combed cotton is a kind of cotton that has been “combed”

- Improved Softness: The combing process removes shorter fibers and other impurities, making cotton smoother and softer to the touch.

- Upgraded durability: Combed cotton fibers have better toughness, are not easy to ball or tear, and will become softer with washing.

- Hypoallergenic: The combing process removes impurities and shorter fibers, so it is less allergenic, making it an excellent choice for those with sensitive or allergy-prone skin.

- Uniform color: the color of combed cotton is more saturated and bright. Because of the high purity of the fiber, the color of the fabric is uniform after dyeing, and there will be no spots.

- On the downside, combed cotton is usually more expensive than regular cotton. Because the combing process is complex, straightening the cotton fibers and removing impurities and shorter fibers makes the yield of cotton cloth smaller.

Leave a Reply

You must be logged in to post a comment.

I am in awe of the creativity and originality you bring to your blog posts.

She has a knack for turning complex concepts into understandable and relatable content in her blog.

They say knowledge is power, and this blog empowers readers by providing a diverse range of informative content. It covers a wide breadth of subjects, making it a reliable source for anyone seeking intellectual growth.