Textile Dyeing Machine-1:Fiber and Yarn Dyeing Machine

Textile dyeing machine is used to dye the textile materials. Due to the various objects of dyeing and finishing processing, such as textile fiber, yarn, woven fabric and knitted fabric. And they have a variety of production methods and technological requirements in the process of dyeing and finishing processing, So there are many kinds of dyeing and finishing process equipment.

Contents

Fiber

Definition of textile fiber

Textile fiber, refers to the fineness is very fine, the diameter is generally a few microns to dozens of microns, and the length is a hundred times larger than fineness, more than a thousand times, flexible and fine material.Such as cotton, leaf collateral, hair and so on.Many different kinds of natural fiber, but not all fiber can be used in textile, spinning weaving, only for a certain length (more than a few millimeters), a certain strength and spinnability of fiber, and can be used in the production of textile products, such as yarn, rope, woven fabric, knitted fabric) can be called the textile fiber, Such as cotton, flax, ramie, wool, silk, viscose fiber, polyester, polyamide fiber, acrylic fiber and so on.

Spinnability refers to the length and fineness of fiber has certain, certain holding force, certain physical and mechanical properties, including strength, elasticity, rigidity, flexibility, abrasion resistance, deformation, etc.), a certain chemical stability (or ordinary chemical solvent insoluble in water, or it is difficult to dissolve), moisture absorption, stain resistance, electrical properties and thermal performance. Only with these conditions, the fiber can meet the requirements of production technology and use.

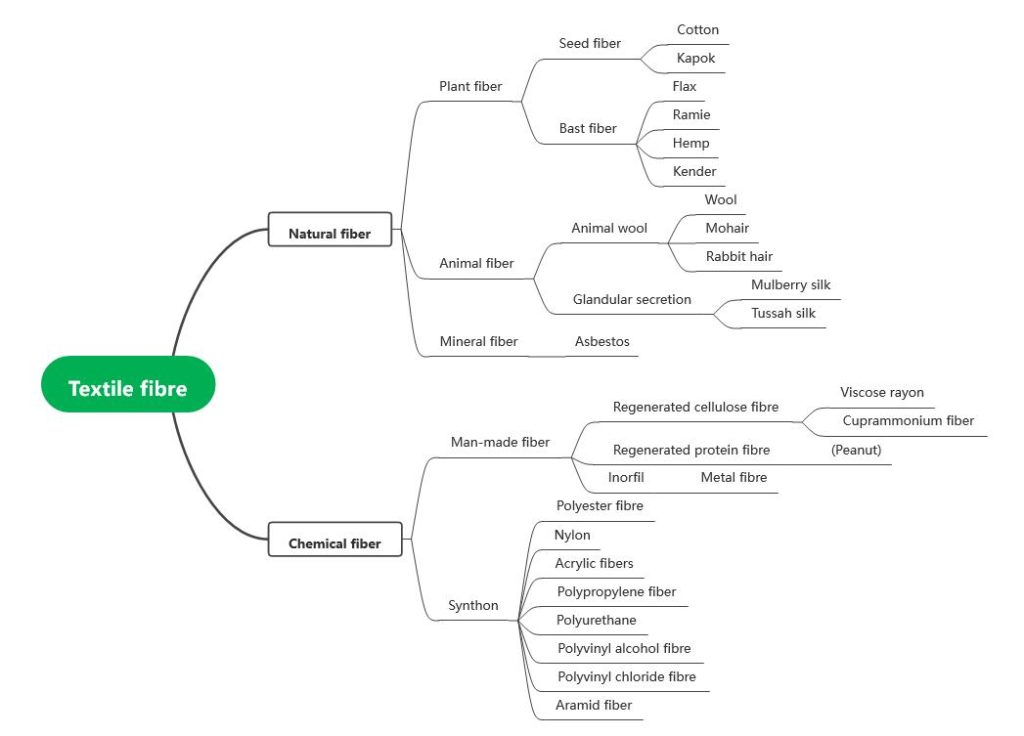

Textile fiber classification

Natural fiber

All in the nature of the original or artificially planted plants, artificially raised animal hair and secreted directly from the fiber, collectively referred to as natural fiber, according to the source is divided into plant fiber, animal fiber and mineral fiber.

- Plant fibers are fibers obtained from seeds, stems, phloem, leaves or fruits of plants, such as cotton and hemp.

- Animal fibers, such as wool or silk, derived from the hair or secretions of animals.

- Mineral fibers, such as asbestos fibers, obtained from fibrous mineral rocks.

Chemical fiber

All the use of natural or synthetic polymers and inorganic materials as raw materials, through artificial processing made of fibrous systems known as chemical fibers. According to the raw materials and production methods for artificial fibers and synthetic fibers.

- Artificial fiber is the largest variety of chemical fiber production, it is the use of cellulose or protein natural polymer material such as wood, bagasse, reed, soybean, cheese as raw materials, through chemical and mechanical processing. For example: sticky fiber, soy protein fiber.

- Synthetic fiber is a kind of chemical fiber, it is used in the petrochemical industry and coking industry byproducts. For example: polyester, polyamide fiber, acrylic fiber, vinylon fiber, polypropylene fiber, and chlorine fiber are all synthetic fibers.

Fiber HTHP dyeing machine

RHS Series IR Dyeing Machine

RHS Series Infra Colour Dyeing Machine is a state-of-the-art textile dyeing machine with IR heating, producing accurate sample dyeing and reproducible results.

Here is the feature of this type of fiber dyeing mahcine:

- Patented IR heating technology at an affordable price;

- Use latest IR heating technology, instead of traditional two-positioned IR heating system, to avoid uneven heating for beakers;

- PLC temperature control system;

- Seamless stainless steel beakers, easy cleaning;

- Clean and fast handling of beakers as well as samples;

- Air cooling system, no need for water source and can reduce operation cost.

ACCDYER-24 Dyeing Lab Machine

ACCDYER-24 Dyeing Lab Machine is a state of the art dyeing instrument. This unit produces more accurate lab sample dyeing with level and re-producible results with a low liquor ratio for diverse fibers. New generation of versatile lab dyeing machine adopts new structure of patented technology, heat method and temperature control method with our own proprietary intellectual property rights. With accurate temperature controlling and stable repeatability, it is precisely used for dyeing trial and sample duplication on the site. With the new design concept of environmental protection and economy, it can achieve the dyeing trial with high saving and zero discharge, easy and simple operation.

HS Series HTHP Dyeing Lab Machine

HS Series HTHP Dyeing Lab Machine is a universal laboratory dyeing apparatus for formulation of production recipes. It is applicable to dye knitted fabric, woven fabric, yarn, loose fibers or zipper. It has a single dyeing bath with hinged lid and magnetic-valve-controlled water cooling coil and a washing sink.

Fiber NTNP dyeing machine

AS Series Water Bath Shaker

AS Series Water Bath Shaker is a normal temperature oscillation type small size dyeing machine, used for simulating the dyeing in actual production process. It can perform evenly mixing of the recipes simultaneously, so that allows more spare time of the operator to increase efficiency.

SHA-B Series Water Bath Oscillator

SHA-B Series Water Bath Oscillator is a constant temperature controlled water bath oscillator, widely used in scientific research institution and academy of plant, biology, microbiology, genetics, viruses, environmental protection, medicine, etc., as essential laboratory equipment.

Yarn

Definition of yarn

Yarn is a linear assembly with continuous length and textile characteristics. Used for weaving, thread making, rope making and embroidery. The quality and appearance of yarn largely determine the wearability and surface characteristics of its products.

Yarn classification

There are many kinds of yarn, different performance, classification methods are also different, generally can be considered from the following aspects.

- Classified by material composition: pure spun yarn, blended yarn, crosstwisted yarn, mixed fiber yarn.

- Classified by fiber length: staple yarn, filament yarn.

- According to the yarn shape structure classification: ordinary yarn, fancy yarn, deformation yarn.

- According to dyeing processing classification: primary color yarn, bleached yarn, mercerized yarn, dyed yarn, color spun yarn.

- Classification by product use: woven yarn, knitting yarn, sewing thread, knitting yarn, special industrial yarn, rope yarn.

Yarn HTHP dyeing machine

The DW202B/241B Series Package Dyeing Machine is a specially-designed textile package first dyeing machine used to dye package yarn under high temperature and high pressure. What’s more, DW241B is equipped with a dye stuff auxiliary supply system, making it suitable for dyeing cotton yarn as well as polyester yarn, wool yarn, etc. DW202B has one dyeing cylinder. Water and dyestuff are added into the cylinder first and mixed evenly. Then place the package of yarn into the cylinder. After the heating tube starts working, the temperature and pressure in the cylinder will rise, and then the bobbin yarn can be dyed effectively in an environment of high temperature and high pressure.

DW241B has an extra service cylinder, connected to the main cylinder. Water and dyestuff are added into the service cylinder and mixed evenly while package yarn is placed in the main cylinder. The mixed dye liquor can be injected into the main cylinder. In the process of dyeing, user can add dye liquor through the service cylinder, no need to open the main cylinder repeatedly, improving efficiency and safety.

Yarn NTNP dyeing machine

SHA-B、AS-12/24 are described in detail above.

Here is the part 1 about textile dyeing machine, more details about fabric dyeing machine and garment dyeing machine will be posted in next blog.

Comments are closed.

I can’t wait to see what the latter two types of textile dyeing machines look like.